Within the modern world, the effectiveness of energy transmission plays a crucial role in various industries, yet often is unrecognized. At the heart of this system are heat exchangers—remarkable devices that allow the efficient transfer of heat between liquids without intermingling them. From power plants to HVAC systems, the applications of heat exchangers are vast and important. They serve as the invisible engines driving energy efficiency, cutting operational costs, and promoting sustainability in countless processes.

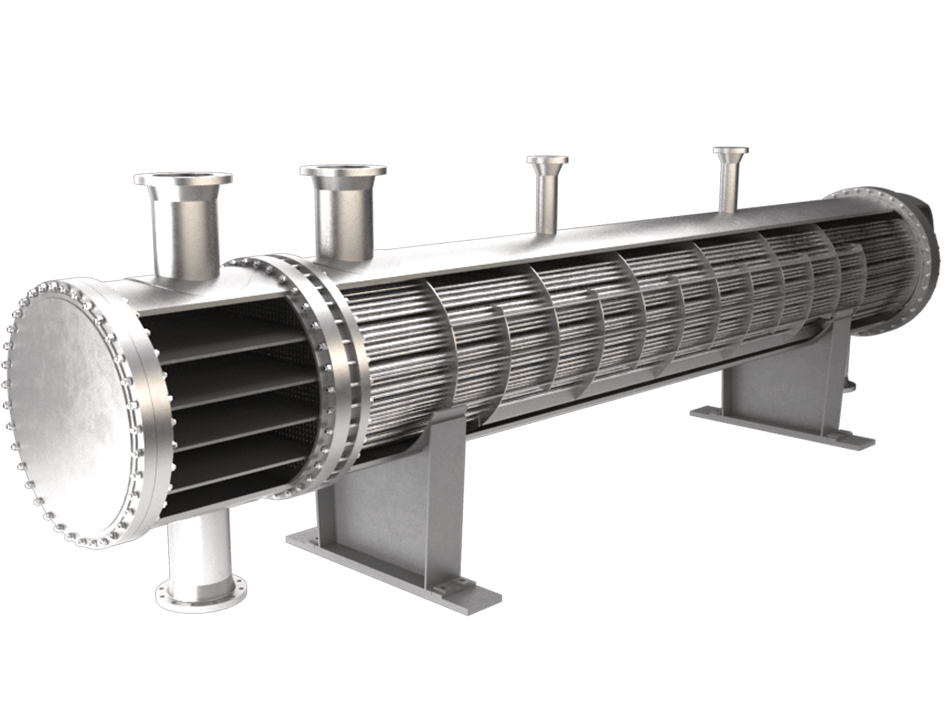

Grasping what a heat exchanger is and how it works can illuminate their value in our daily lives and industries. These devices come in diverse forms, each customized to meet distinct requirements, whether it be a shell and tube design or a more compact plate heat exchanger. As we delve into the different types, their uses, and the upcoming trends in heat exchanger technology, it becomes clear that these underappreciated heroes deserve more recognition for their essential contributions to energy management and environmental sustainability.

Categories and Uses of Thermal Exchangers

Heat exchangers are categorized into several categories, each engineered to meet particular commercial needs. The most common categories include shell and tube, plate, air-cooled type, water-cooled type, and spiral thermal exchangers. Tube and shell thermal exchangers feature a set of tubes, one group carrying the heated fluid and the another carrying the cold fluid, facilitating heat transfer between the two. Plated thermal exchangers, on the other hand, consist of multiple thin plates stacked together, providing a large surface area for efficient heat transfer. Each design offers distinct benefits, making it essential to select the right type depending on the use.

The uses of thermal exchangers are vast and diverse. In the HVAC industry, they play a key role in maintaining pleasant indoor temperatures by exchanging thermal energy between air and liquids. Power plants rely on heat exchangers to convert energy effectively, using them in cooling units and coolers. In the chemical processing sector, these systems assist in regulating the heat of reactions, ensuring optimal product quality while maintaining safety requirements. The food and drink sector also employs thermal exchangers for pasteurization and cooling processes, highlighting their importance in maintaining product integrity.

Moreover, heat exchangers are integral to renewable energy systems, such as photovoltaic and geothermal installations, where they improve energy capture capabilities. The car sector employs thermal exchangers to control engine heat levels, ensuring efficiency and safety. As industries strive for greater energy effectiveness, the role of thermal exchangers keeps to grow, showcasing their vital contribution to eco-friendly practices.

Efficiency and Upkeep of Heat Exchangers

Maintaining the efficiency of heat exchangers is crucial for maximal functionality in various industrial applications. Efficient heat transfer relies on the cleanliness and functionality of the heat exchanger surfaces. Contamination, which refers to the buildup of undesirable materials on heat transfer surfaces, can significantly impair efficiency by reducing heat transfer rates. engineering plans for hot water loop and the use of suitable cleaning techniques are critical to minimize fouling and ensure that heat exchangers operate at their best. Tracking the thermal performance and pressure drops can also help in determining when maintenance is needed.

Consistent maintenance not only extends the lifespan of heat exchangers but also enhances their energy efficiency. Implementing a preventive maintenance program can include visual inspections, performance testing, and monitoring of operating pressures and temperatures. Such proactive measures can help identify early signs of deterioration or failure, allowing for prompt repairs that can prevent more extensive and costly interruptions. Additionally, digital monitoring technologies have made it easier to monitor performance metrics in the moment, further improving maintenance strategies.

When selecting heat exchangers for specific applications, it is crucial to consider not just their initial efficiency but also their maintenance requirements over time. Different designs, such as gasketed plate heat exchangers, offer simpler access for cleaning and servicing compared to other types. Choosing components and designs that facilitate maintenance can lead to reduced operational costs and increased reliability. Overall, a thoughtful approach to both the efficiency and maintenance of heat exchangers is vital for maximizing their performance and ensuring their long-term viability in various industries.

Innovations and Next-Generation Trends in Heat Exchange Systems

As industries work for greater energy-saving measures and environmental responsibility, breakthroughs in heat exchange systems are essential. One of the most noteworthy developments is the progress of micro-channel heat exchangers. These units have channels that are substantially smaller than those found in conventional models. This small form factor offers enhanced heat transfer performance while minimizing the refrigerant charge, resulting in decreased energy expenses and less environmental harm.

Another exciting trend is the integration of automated technology into heat exchange systems. With the growth of the Internet of Things, manufacturers are prepared to embed smart sensors and real-time monitoring solutions. These innovations allow for real-time information gathering and evaluation, resulting in improved maintenance practices and enhanced efficiency in operations. Proactive servicing, driven by analytical insights, can help prevent breakdowns and extend the operational life of heat exchangers, making them even more reliable.

Finally, the investigation of new materials is set to change the design of heat exchangers. Innovations such as advanced composites and materials derived from graphene offer significant advantages in terms of heat transfer efficiency and durability against corrosion. These substances can potentially reduce the total weight of thermal devices while maintaining or boosting their effectiveness. As investigations advance, we may witness a next wave of heat exchange solutions that are more lightweight, higher in efficiency, and more qualified to meet the demands of current industry practices in various industries.